The Working Principle of Automatic Bollards

Working Principle of Hydraulic Automatic Bollards

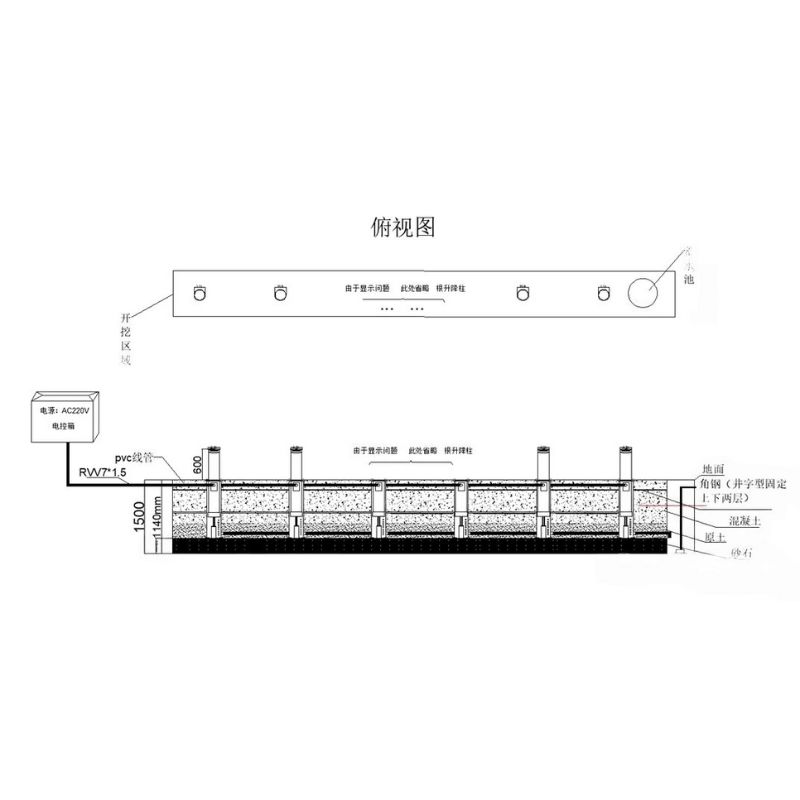

Hydraulic automatic bollards use a technology similar to the piston principle, where hydraulic oil flows through the system to control the rise and fall of the bollard. Below is the working process of hydraulic automatic bollards:

Hydraulic System Drive

The hydraulic oil is pressurized by a vane pump, then passes through a filter, explosion-proof electromagnetic directional valve, throttle valve, hydraulic one-way valve, balance valve, and other components of the control system. It enters the lower end of the hydraulic cylinder, causing the piston inside the cylinder to move upwards, which drives the bollard to rise. When the hydraulic cylinder's upper end returns oil, it flows back to the oil tank through the explosion-proof electromagnetic directional valve. The pressure in the hydraulic system is regulated by the relief valve.

Lift and Lower Control

When the piston of the hydraulic cylinder moves downward, hydraulic oil flows through the explosion-proof electromagnetic directional valve into the upper end of the hydraulic cylinder. The return oil from the lower end of the cylinder flows back to the oil tank through the balance valve, hydraulic one-way valve, throttle valve, and explosion-proof electromagnetic directional valve. The balance valve ensures steady pressure, preventing the descent from being affected by changes in weight. The throttle valve is used to regulate the flow and control the speed of ascent and descent.

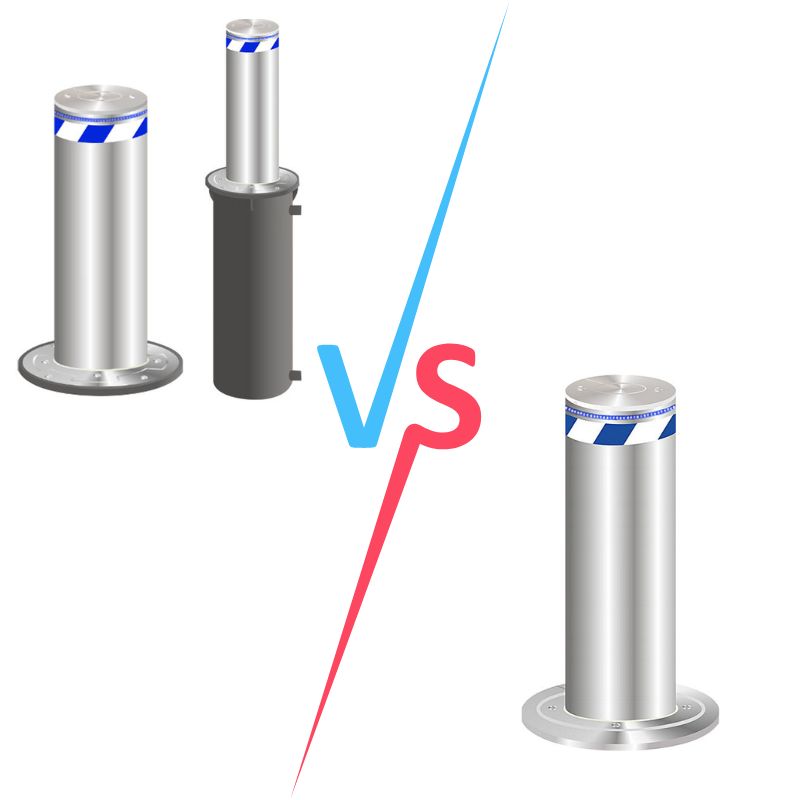

Hydraulic systems are more complex than electric systems, with more components, but they offer higher safety and stability. Hydraulic-driven automatic bollards typically use in-chamber hydraulic technology and sealed designs, making the system more compact and reliable.

Power Conversion and Torque Control

The power of the hydraulic automatic bollard is converted from the hydraulic system into lifting force through the action of the piston and then transferred to an eccentric wheel center via a connecting rod, generating torque that drives the crankshaft to rotate. This torque causes the automatic bollard to rise and fall. Due to differences in piston cylinder designs, the torque generated by each piston cylinder is also different, ensuring smooth and precise lifting and lowering operations.

Working Principle of Pneumatic Drive Automatic Bollards

Pneumatic drive automatic bollards combine electric gas springs with drive motors to control the bollard’s motion using both air pressure and electric drive. The system consists mainly of electric gas springs and motors, which work together to lift and lower the bollard through a simple control method.

Simplified Design and Efficient Control

The main advantage of pneumatic automatic bollards lies in their simple structure, ease of control, and lower cost. The electric gas spring works by energizing the motor, which drives the pull rod, pushing the bollard up and down. This simplified design results in a lower cost system while still providing good lifting performance and high stability.

Miniature Hydraulic Drive System

Fully automatic bollards are typically equipped with a miniature motor and an integrated hydraulic cylinder drive system. This system, through a micro-integrated design of mechanical, electrical, and hydraulic components, enables independent control of the automatic bollard. Each bollard operates as an independent unit, ensuring high reliability and safety.

Emergency Release System

To handle emergencies like power outages, automatic bollards are equipped with an emergency release system. During a power failure, operators can manually activate the release system to quickly lower the bollard, ensuring that traffic can pass through or areas remain securely accessible.

Applications of Automatic Bollards

Automatic bollards are widely used in road traffic management, parking systems, and vehicle control in sensitive areas. They are often used in conjunction with barrier gates, parking systems, and other security devices but can also operate independently. The primary function is to prevent unauthorized vehicles from forcibly entering sensitive areas, ensuring security. They offer high practicality, reliability, and safety, making them particularly suitable for high-security locations such as government offices, financial institutions, airports, and more.

Conclusion

As an essential facility in modern traffic management, automatic bollards operate based on complex hydraulic and pneumatic technologies. Whether hydraulic or pneumatic, each type of automatic bollard has its own advantages and specific applications. Understanding the working principle of automatic bollards helps improve maintenance and management, ensuring smooth and secure traffic control.

By regularly maintaining and monitoring the operational status of automatic bollards, you can extend their lifespan, reduce failures, and ensure efficient operation.