What is the Difference Between Automatic Bollards and Regular Bollards?

Many people may still be unclear about the differences between automatic bollards and regular bollards. The market for road safety equipment is vast, with various types and models available, allowing users to choose according to different needs. Below, we will delve into the key differences between these two types of bollards.

Automatic Bollards

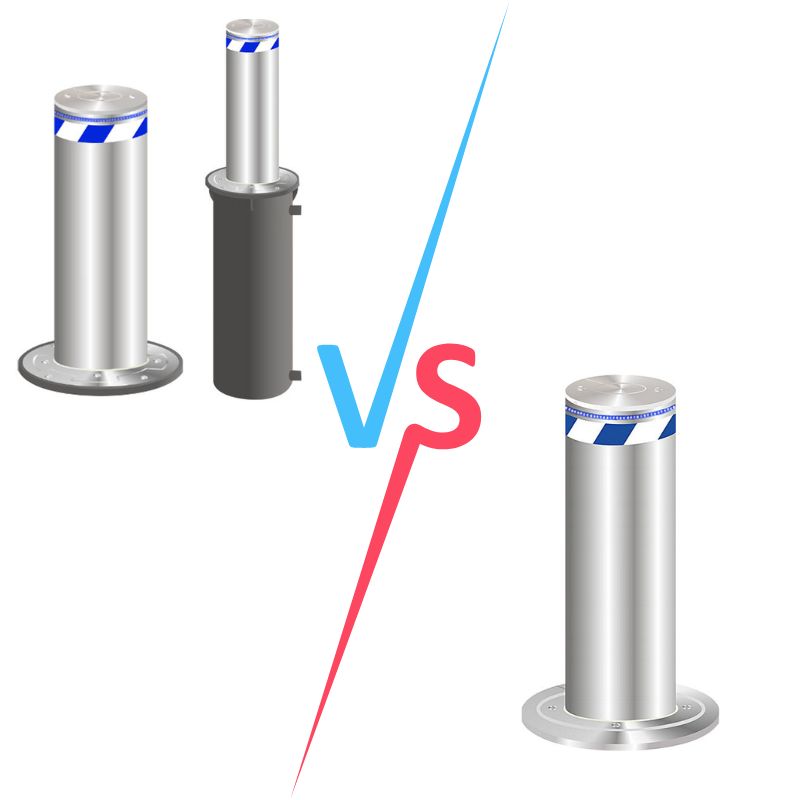

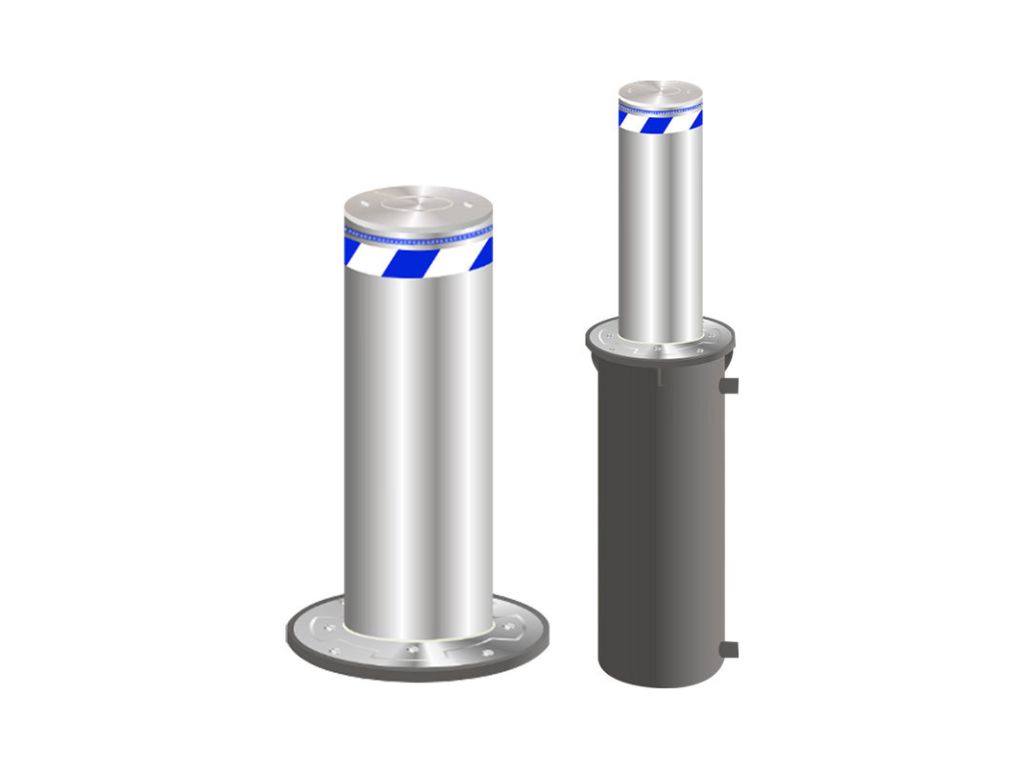

An automatic bollard is a type of bollard that can be raised or lowered either manually or automatically. It is primarily used for managing vehicle access and controlling restricted areas. Depending on the control method, automatic bollards can be classified into manual, semi-automatic, and fully automatic types. These bollards offer great flexibility, as they can be raised or lowered as needed, making them ideal for high-security areas such as government buildings, banks, prisons, and large corporate campuses. When no vehicles are passing through, automatic bollards can effectively block unauthorized vehicles, enhancing security.

Regular Bollards

Regular bollards are generally divided into plastic and steel types. Plastic bollards include traffic cones and reflective warning posts, which are mainly used for traffic control. In everyday life, we often see traffic cones marking maintenance areas on roads. Reflective warning bollards are more commonly found around residential areas, especially at the bottoms of parking spaces or at road corners to alert passing vehicles.

Among steel bollards, stainless steel is the most common material. These bollards are often used to separate vehicles in traffic control, such as restricting parking on the sides of roads. Due to market demand, some large parks and shopping malls also install regular bollards at entrances, where aesthetic appearance and impact resistance are more important. Stainless steel, with its polished surface and corrosion-resistant properties, is ideal for such outdoor installations.

Key Differences

Installation Method

-

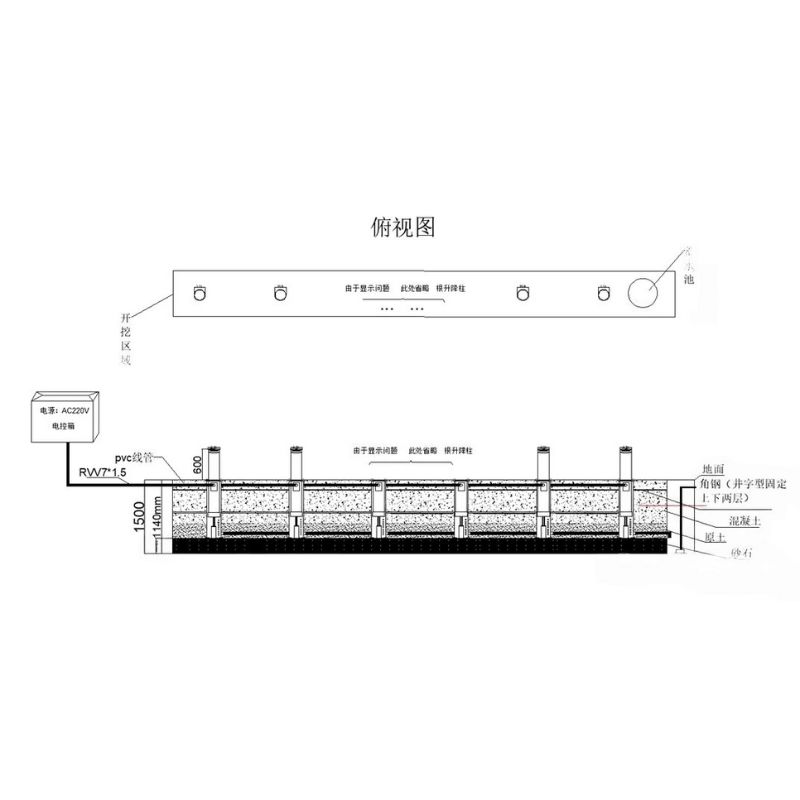

The installation of automatic bollards is relatively complex. It requires digging underground slots and setting the bollard in place. Specifically, for hydraulic automatic bollards, a trench needs to be dug, typically about 1-1.5 meters wide and 40 cm deep, to accommodate the embedded bollard and drainage systems. The installation process is quite intricate. Additionally, automatic bollards require a control system to manage their rise and fall.

-

Regular bollards are simpler to install. They are typically fixed to the ground using screws and do not require extensive groundwork, making them ideal for locations with tight construction timelines. As long as the surface is stable and flat, installation is straightforward.

Application Scenarios

-

Due to their ability to dynamically control vehicle passage, automatic bollards are best suited for areas with high security needs and traffic control requirements. For example, government agencies, military bases, banks, and prisons can use automatic bollards to ensure only authorized vehicles pass through at certain times.

-

Regular bollards are used in places where clear boundaries need to be established, such as construction zones, parking lots, and commercial districts. Since they are fixed in place, regular bollards are mainly used for traffic guidance and warning, rather than providing dynamic passage control.

Safety and Impact Resistance

-

Automatic bollards offer strong impact resistance, especially hydraulic models, which are designed to withstand vehicle collisions. They can quickly rise to form a protective barrier, making them suitable for areas requiring high-level security, such as the entrances to important institutions. The impact resistance of automatic bollards is far superior to that of regular bollards, offering better protection.

-

Regular bollards, particularly plastic ones, are primarily used for marking and have relatively weak impact resistance. Steel bollards do provide some protection, but they cannot match the strength of automatic bollards. In cases of significant impact, fixed bollards may not effectively absorb or block the force of a collision.

Cost Differences

-

Due to the complex mechanical or hydraulic systems involved, automatic bollards have higher installation and maintenance costs. Fully automatic hydraulic bollards, in particular, are more expensive to purchase and maintain. As a result, they are most suitable for high-security areas, though their cost limits their use in smaller or less critical locations.

-

Regular bollards, especially plastic types, are more affordable to manufacture and install. For locations that do not require dynamic traffic control, regular bollards offer a cost-effective and practical solution.

Usage and Maintenance

-

Automatic bollards require regular checks and maintenance, particularly for their hydraulic systems and control circuits, to ensure their raising and lowering functions operate smoothly. Troubleshooting may require professional technical support, making maintenance more complex.

-

Regular bollards require simpler maintenance, mainly checking for stability, damage, or wear. They also need occasional cleaning and repairs. Compared to automatic bollards, regular bollards are easier and less costly to maintain, making them ideal for areas with less stringent flexibility requirements.

Conclusion